Robotics Arm & Manipulators

- Home

- Siemens Products

- Robotics Arm & Manipulators

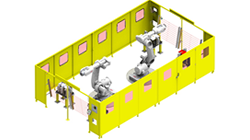

// Robotic Arm Range

Robotics Arm & Manipulators

- Arc Welding Automation

- Spot Welding Automation

- Material Hnadling Automation

- Customize Handling Manipulators

- Vision and Inspection System

- Press Line Automation

- Battery Assembly Automation

- Special Purpose Machine

Two Wheeler

Fuel Tank

Silencer

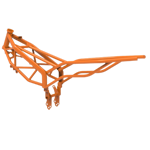

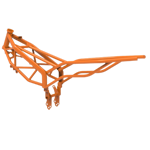

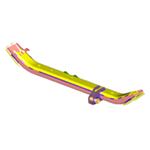

Swing Arm

Other Child Parts

Four Wheeler

Main Member Assembly -3W

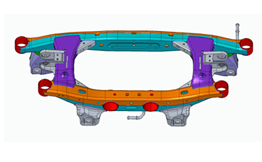

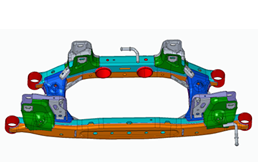

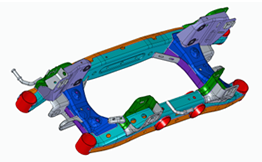

Cradle Assembly- 4W

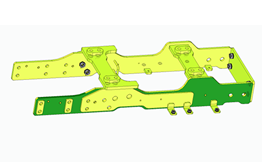

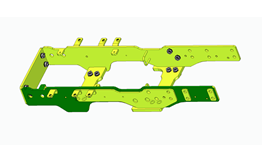

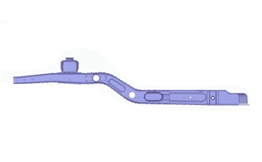

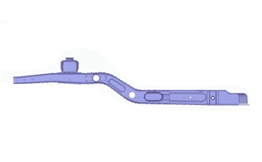

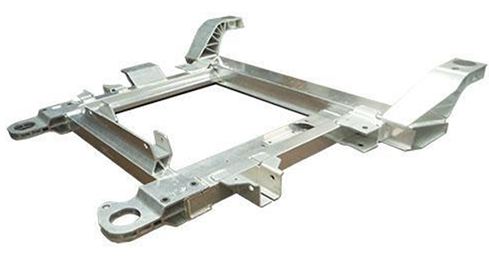

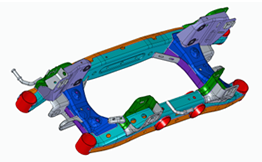

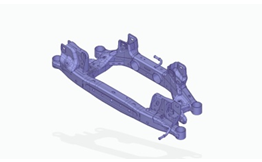

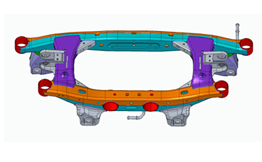

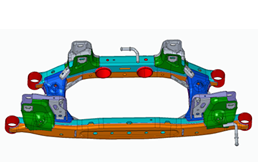

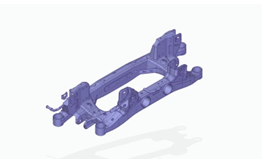

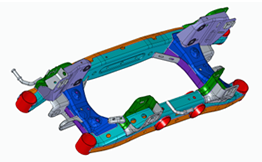

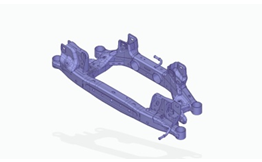

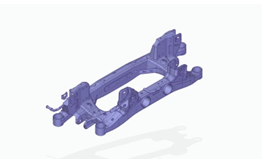

Sub Frame – 4W

Front Arm – 4W

Other – 4W.

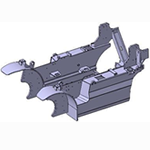

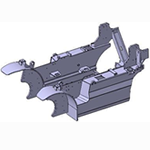

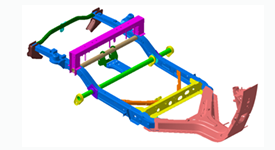

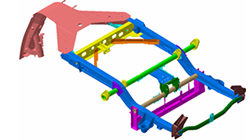

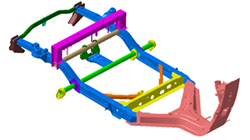

Four Wheeler: Main Member Assembly

Optimized Welding Parameters

Minimal Material Distortion

Speed and Efficiency

Consistency

Precision and Consistency

Excellent Welding Quality

Flexibility for model change

Railway Industry

Tractor Chassis

Control Support

Fork Lift Chassis

Other Parts

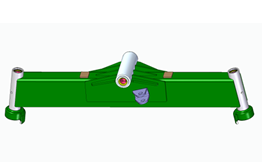

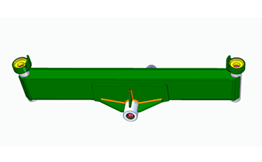

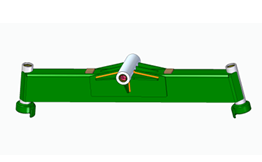

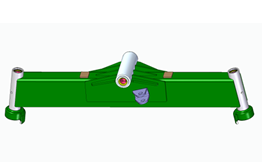

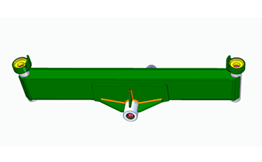

Heavy Fabrication: Axles

Tractor Front Axle

2 No of robots

1 min Cycle time

Penetration with welding Quality

Fixture with Flexibility

Consistent Welding Reducing Waste

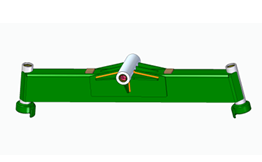

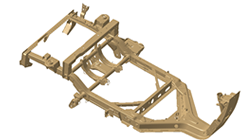

Heavy Fabrication: Chassis

Fixture with Flexibility

Consistent Welding Reducing Waste

Spot Welding Systems for 3 Wheeler

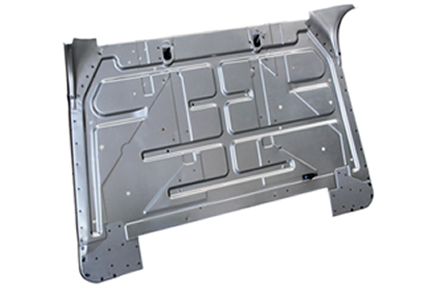

Floor Board

Frame 3W

Main member

Upper Part

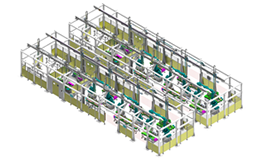

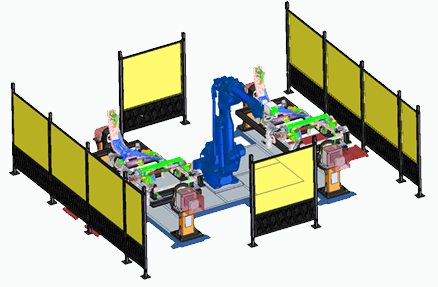

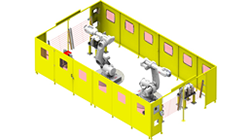

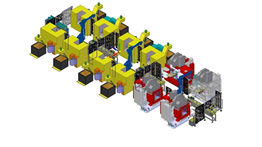

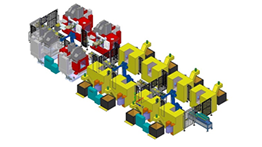

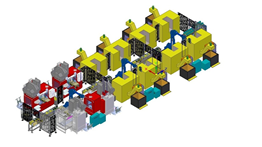

3 Wheeler: Main Member Building Line

16 No of robots

Twin Spot Welding Gun

Completely Automated Line

Part transfer by Overhead Gantry

Speed and Efficiency

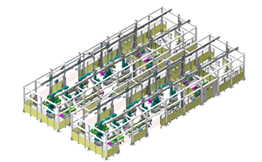

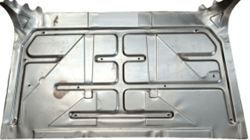

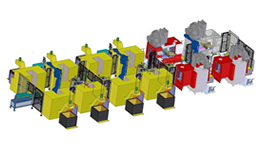

3 Wheeler: Floor Board

High Volume Line- 2400 Parts per day

Twin Spot Welding Gun

8 Variety of parts manufactured on single line without changing the fixture

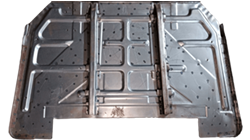

3 Wheeler: Frame

Completely automated line including handling and loading

4 Variety of parts manufactured on single line without changing the fixture

Spot Welding Systems for 4 Wheeler

Seat Frame

Silencer Shield

Other Body Components

Spot Welding of Seat Frame

System supplied to Premium Automaker

Completely Automated Line

Safety and Efficiency

Speed with Precision

Spot Welding of Silencer Shield

Variety of parts manufactured on single line without changing the fixture

Quality and Efficiency

Speed with Safety

Other Parts Spot Welding

ATC according to need of Project

Fixture Changeover Flexibility

Flexible Production

Speed And Efficiency

Automotive Heavy Vehicles

We provide Spot welding system to Heavy Vehicle manufacturers

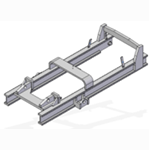

Heavy Load Gantry System

Provided In-house Designed and Developed Gigantic Gantry System to handle Railway Wagon wheel of 1.4 Ton through the manufacturing process.

Process Line Automation

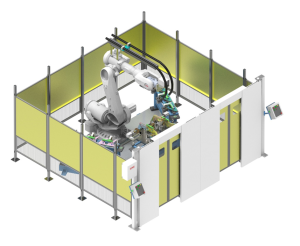

Chemical Industry Automation

Provided Robotic handing System for handling of barrel of 1.2 tons in a chemically hazardous environment.

Robot Reach- 4000 mm

In-house Designed Grippers

Chemically Hazardous Environment

Fiber Sheet Handling Automation

We’ve provided an end-to-end system for fiber sheet manufacturing, overseeing processes from raw material handling to final inspections, including marking and cutting.

Battery Handling Automation

We have implemented a comprehensive solution for managing the entire production process of lead acid batteries. This production line includes various critical stages such as vision inspection, assembly, leak testing, as well as HRD and other essential quality testing procedures.

Manufacturing Line Automation

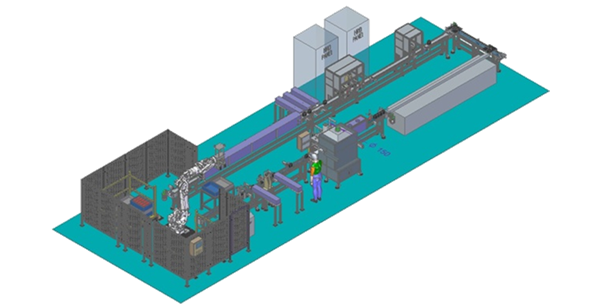

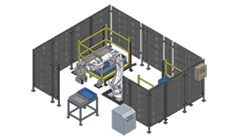

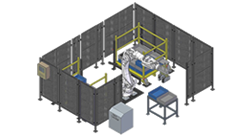

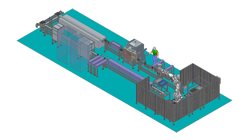

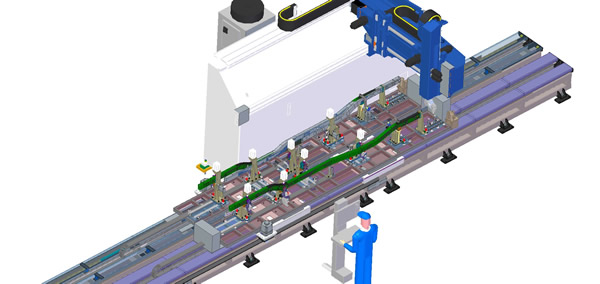

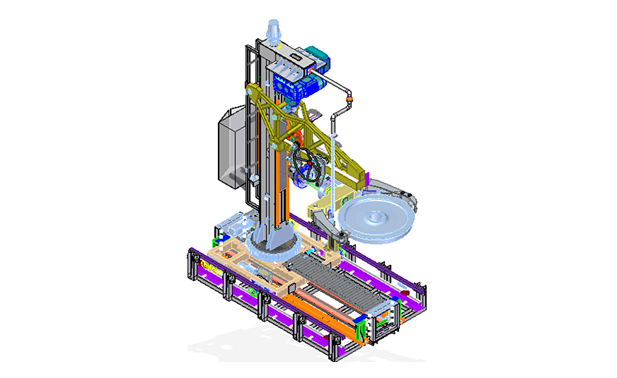

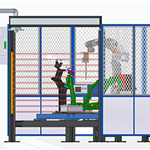

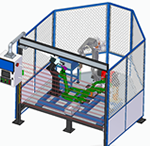

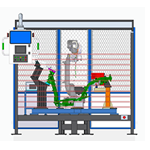

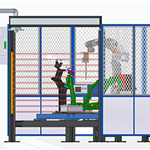

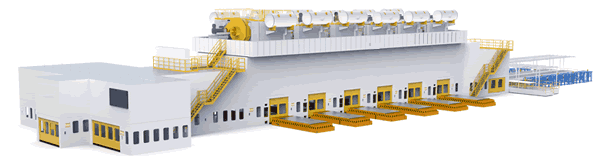

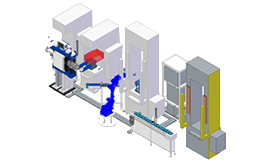

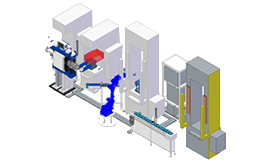

Engine Valve Manufacturing Automation

Completely Automated manufacturing Line

Robot, Gantry and Pneumatic systems for handling

Accuracy: 10-15 Micron

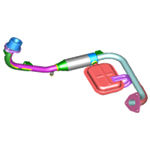

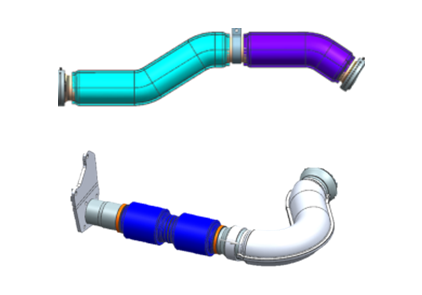

![cm01[1]](https://irobotics.co.in/wp-content/uploads/2023/10/cm011.png)

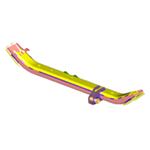

![cm02[1]](https://irobotics.co.in/wp-content/uploads/2023/10/cm021.png)

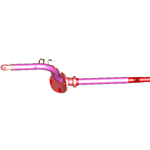

![cm03[1]](https://irobotics.co.in/wp-content/uploads/2023/10/cm031.png)

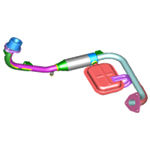

![cm04[1]](https://irobotics.co.in/wp-content/uploads/2023/10/cm041.png)

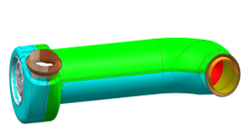

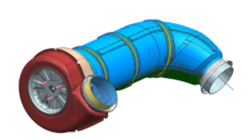

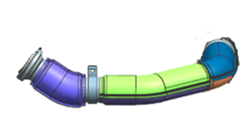

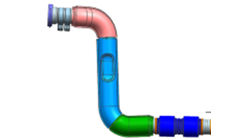

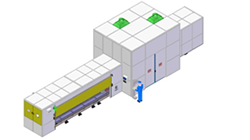

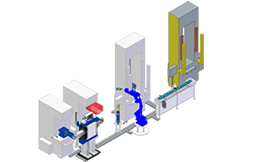

Oil and Gas Component Manufacturing

We’ve delivered complete automation for an Oil and Gas component, utilizing robots for loading an unloading part for machining and a vision system for quality inspection.

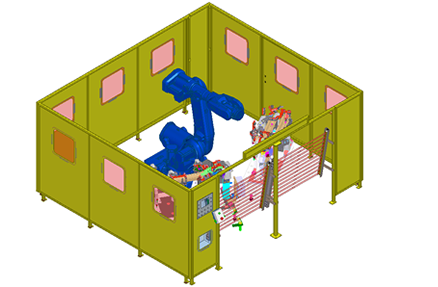

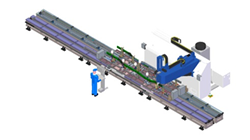

Laser Cutting Handling Automation

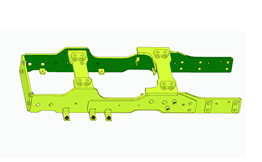

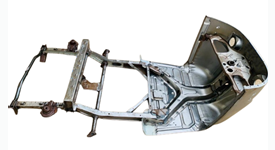

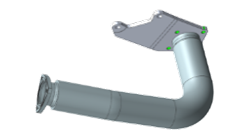

Automobile Chassis – Sub Frame

We’ve delivered a complete solution for laser cutting automobile chassis sub-frames, ensuring precision and efficiency in manufacturing processes.

Machine Tending Automation

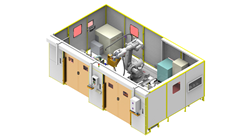

4 Wheeler Engine Components

Specially designed Gripper to handle all the 3 varieties

No Change Over required

System designed with Standards of Premium Automaker

Agriculture Industry

We have supplied system to handle various components of Farm Equipment’s

Rear axle housing

Rotavator blade

End of Line Automation

We specialize in offering End-of-Line Automation solutions, streamlining the final stages of production processes. Our expertise ensures efficiency and precision in the automation of crucial tasks at the end of the manufacturing line, enhancing overall productivity and product quality.

Handling Manipulator for Chemical Industry

Robot Payload- 1.7 Ton

Robot Reach- 4000 mm

In-house Designed Grippers

Chemically Hazardous Environment

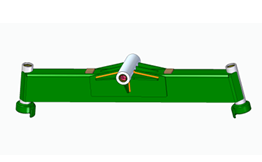

Handling Manipulator for Railway Industry

Manual and Automatic Control

360 Degree Rotating Axis

Received award for the development of this product

Part Present Absent System

We provide Robotic Part Present Absent System to understand if all parts are attached to an assembly (Frame of Two Wheeler) or not.

Data Collection and Display of the same

High Inspection Speed and Accuracy

Dimension Inspection

We’ve provided an advanced Vision Dimension System for the meticulous inspection of automotive components. Key features include:

Adaptive System: Identifies the part, selects the appropriate program, and conducts inspections accordingly

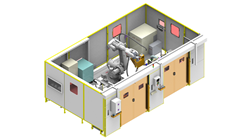

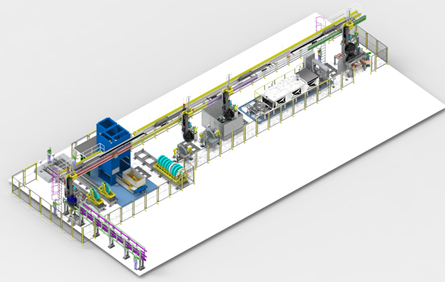

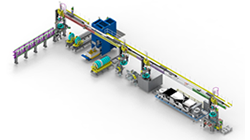

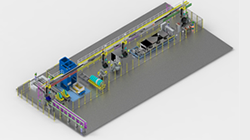

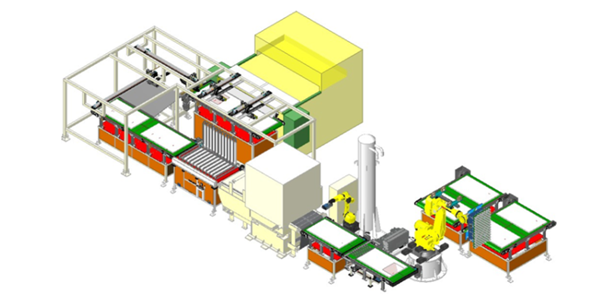

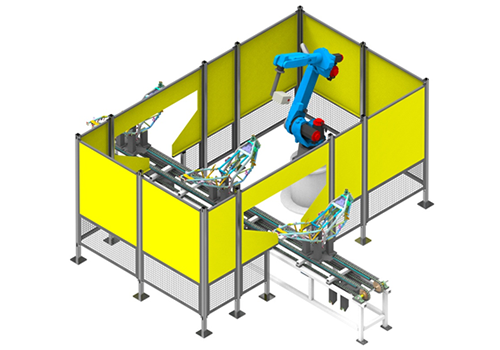

Press Line Automation

we are dedicated to supplying cutting-edge automation solutions for press lines. With a commitment to innovation and excellence, we craft bespoke systems tailored to the unique needs of our clients. Our expertise spans various industries, and we take pride in providing top-tier automation solutions that enhance efficiency, precision, and productivity. Whether it’s the automotive sector, aerospace industry, or beyond, our solutions redefine how press lines operate.

High Speed Stamping Robot

Suitable for press spacing at 5.5-8m

Remote Monitoring

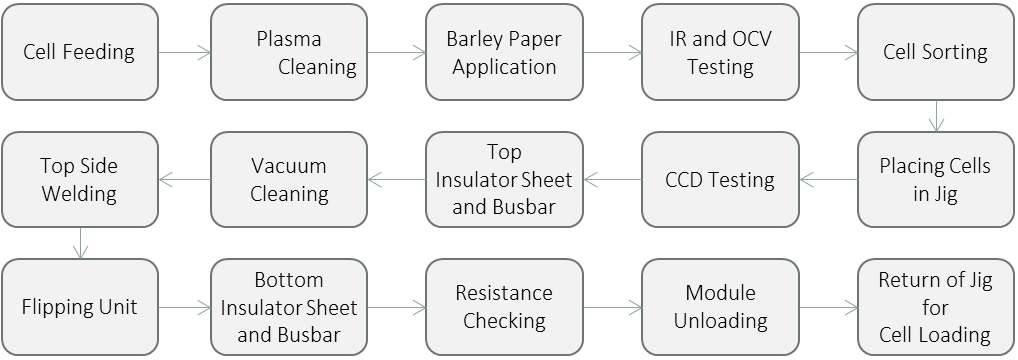

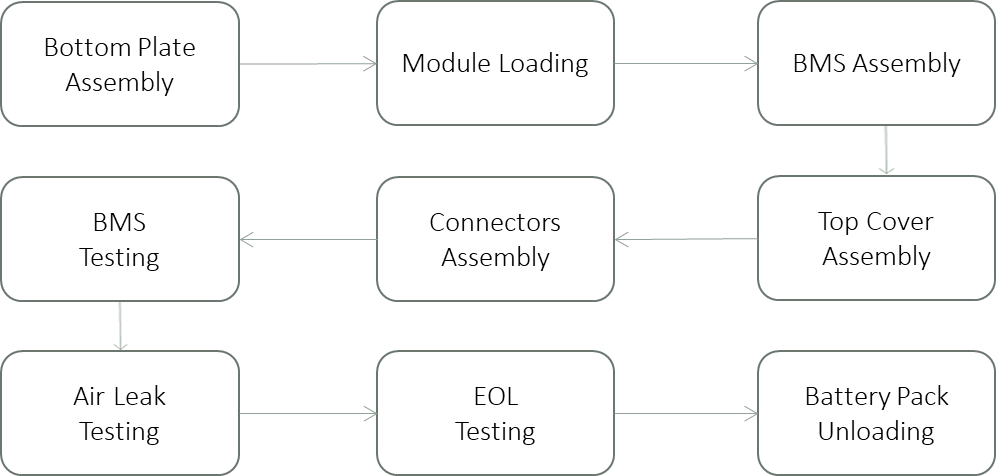

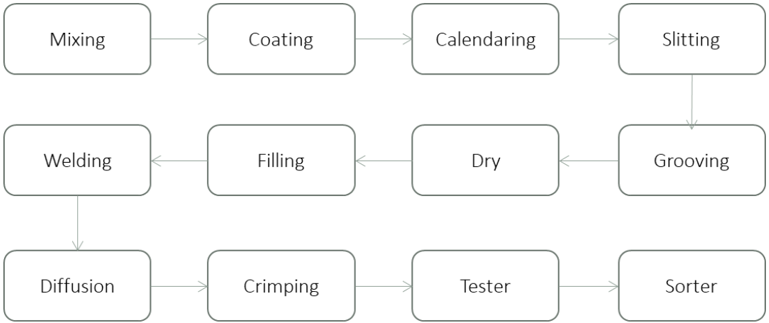

EV Battery Solutions

We excel in delivering cutting-edge solutions for the automation of EV battery manufacturing.

Our expertise spans various aspects, including:

Module to Pack Assembly Automation

Cell Manufacturing Automation

Comprehensive Busbar Manufacturing Line Solutions

Cell to Module Assembly Line

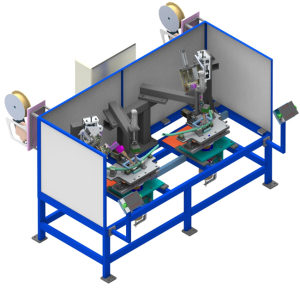

Machine Tending for Spot Welding of EV Cells

We’ve automated the loading of battery modules into spot welding machines, enabling precise spot welding of cells and busbars. Remarkably, a single robot efficiently manages six machines simultaneously, streamlining the production process.

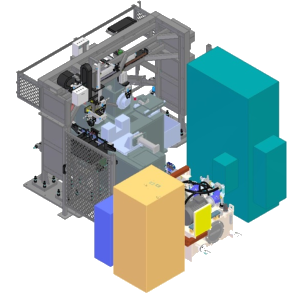

Module to Pack Assembly Line

Cell Manufacturing Line

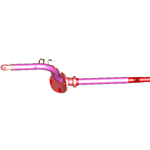

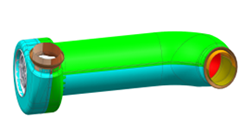

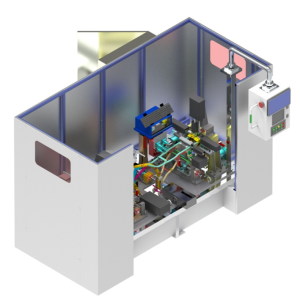

Arc Welding SPM

We supply SPM for welding of various parts including 360 Degree round weld for components like Swing arm, Suspension Seat Etc.

Stud Welding SPM

We specialize in designing and engineering Stud Welding Special Purpose Machines (SPM) for efficient and precise stud welding. Our tailored SPMs offer robust and reliable performance, catering to diverse industry needs, including high-speed production and complex welds.

Friction Welding Handling SPM

We excel in supplying cutting-edge Friction Welding Special Purpose Machines (SPM). These innovative systems optimize friction welding, guaranteeing superior quality, efficiency, and precision. Ideal for automotive, aerospace, and various industries, our SPMs ensure exceptional performance, reliability, and productivity, meeting your welding needs with efficiency and excellence.

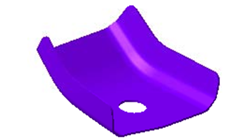

Auto correction Machines

Auto Correction Machine is used for correcting the distorted frame after the welding process. It maintains the shape and desired dimensional accuracy for the frame.